eVTOL wing

One target application of PENGoLINS is to integrate design and analysis of aerospace structures. We first show the creation of an electric vertical takeoff and landing (eVTOL) aircraft wing geometry with NASA’s OpenVSP. Then perform structural analysis to compute the stress distribution using PENGoLINS. Full Python file of this demo is implemented here.

Design of eVTOL wing geometry

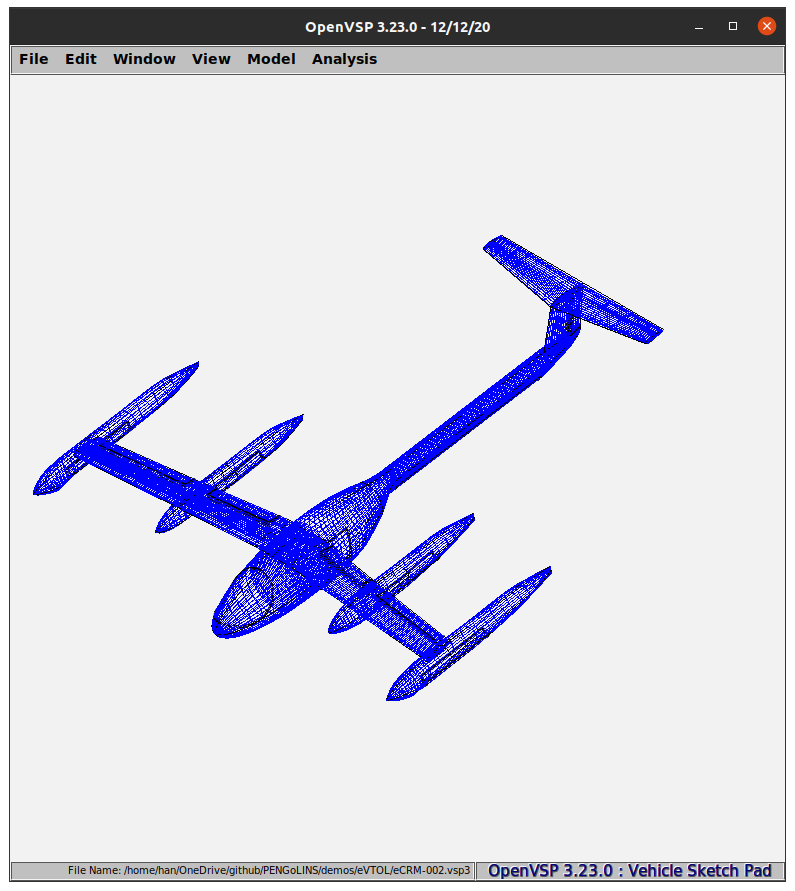

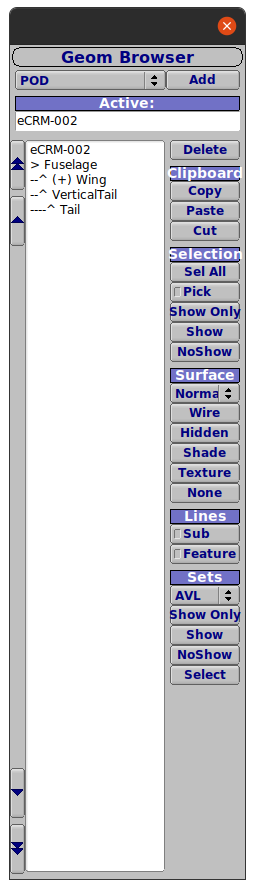

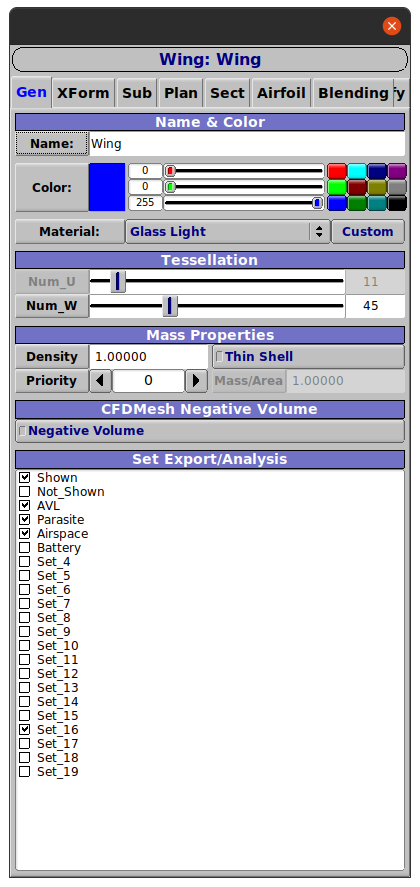

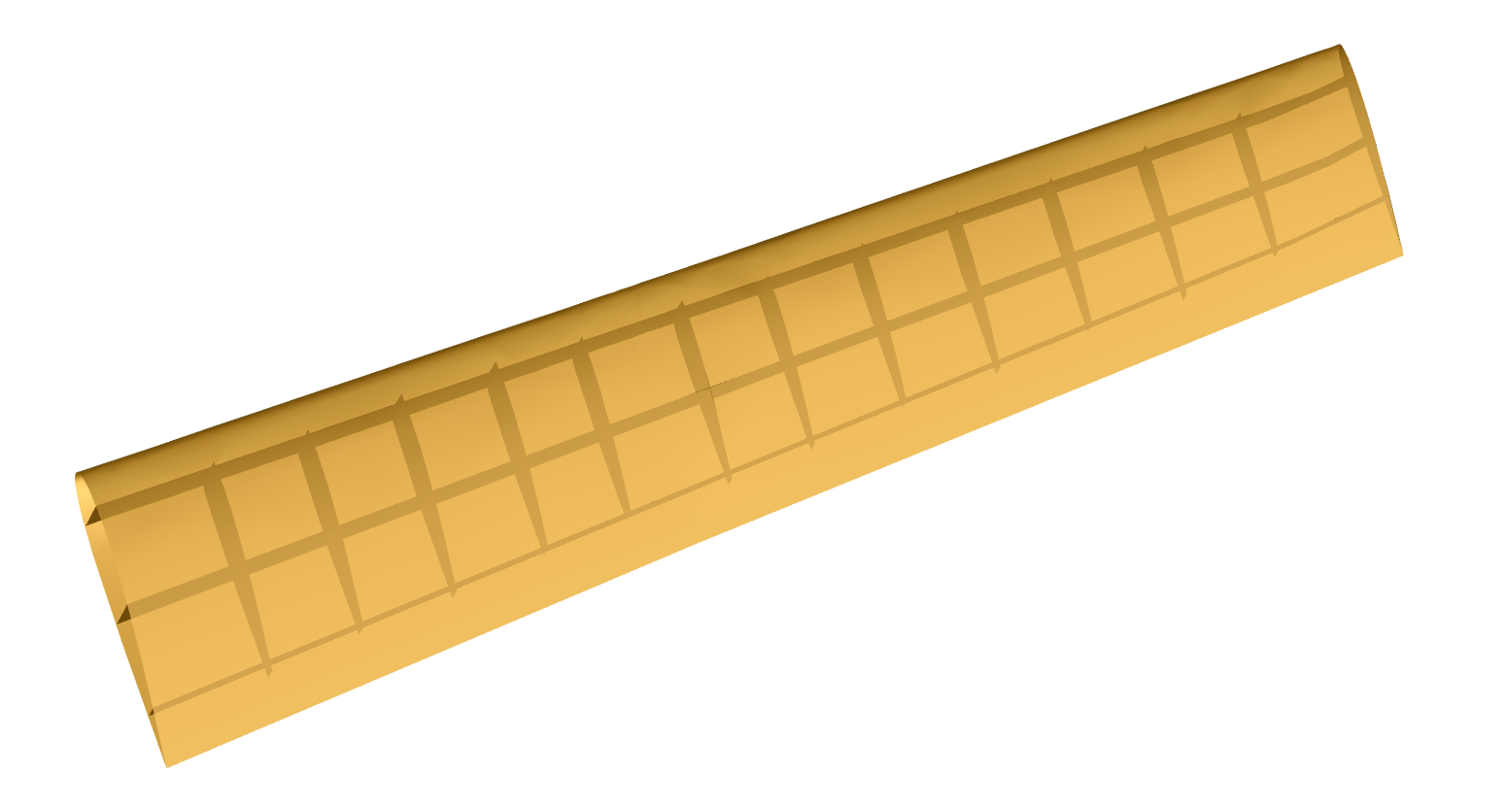

OpenVSP is a geometry tool that allows users to generate aircraft components, such as fuselages, wings, and pods, by adjusting design parameters. We start with an existing eVTOL geometry eCRM-002, which can be obtained from the public database VSP Hangar, to get the outer skin of the wing. A screenshot of the eCRM-002 in OpenVSP, and its associated geometry browser and wing design interface are shown below.

Although OpenVSP is a powerful geometry design software, it doesn’t provide the functionality to specify internal stiffeners for aircraft. Therefore, we use an auxiliary geometry tool that creates NURBS surfaces to represent ribs and spars of the eVTOL wing, so that the stress analysis is more practically meaningful. We introduce 3 spars and 12 ribs using the auxiliary tool for one wing. The exported eVTOL geometry with internal structures can be downloaded here in igs format. Moving the geometry to the current directory, we can proceed with the structural analysis.

Geometry preprocessing

To begin with, we import PENGoLINS.occ_preprocessing for the preprocessing of geometry and PENGoLINS.nonmatching_coupling for analysis.

from PENGoLINS.occ_preprocessing import *

from PENGoLINS.nonmatching_coupling import *

Define material and geometric parameters, spline order, and penalty coefficient.

# Scale down the geometry using ``geom_scale``to make the length

# of the wing in the span-wise direction is around 5 m.

geom_scale = 2.54e-5 # Convert current length unit to m

E = Constant(68e9) # Young's modulus, Pa, assuming aluminum

nu = Constant(0.35) # Poisson's ratio

h_th = Constant(3.0e-3) # Thickness of surfaces, m

p = 3 # spline order

penalty_coefficient = 1.0e3

Now, we import the downloaded igs file and convert them to OCC recognizable B-spline surface instances.

print("Importing geometry...")

filename_igs = "eVTOL_wing_structure.igs"

# Read the igs file into current process and treat the geometry

# as a list of topological shapes by setting ``as_compound``

# to ``False``.

igs_shapes = read_igs_file(filename_igs, as_compound=False)

# Convert the topological shapes to B-spline surfaces that

# can be recognized by pythonOCC.

evtol_surfaces = [topoface2surface(face, BSpline=True)

for face in igs_shapes]

The python list evtol_surfaces contains all patches of the aircraft. Since we want to perform analysis for the wing only, the next step is to isolate the NURBS surfaces of the wing and its internal structures by specifying their indices. 21 NURBS surfaces are selected for analysis in this demo.

# Outer skin indices: list(range(12, 18))

# Spars indices: [78, 92, 79]

# Ribs indices: list(range(80, 92))

wing_indices = list(range(12, 18)) + [78, 92, 79] + list(range(80, 92))

wing_surfaces = [evtol_surfaces[i] for i in wing_indices]

num_surfs = len(wing_surfaces)

Before running the analysis, it’s nontrivial to check the continuity of the NURBS surfaces so that all patches are sufficiently smooth to apply the Kirchhoff–Love shell formulation, which requires $C^1$ continuity. Looking at the knots vectors of NURBS surfaces in wing_surfaces, the excessive multiplicity of interior knots leads to $C^0$ continuity of basis functions. Therefore, we need to reconstruct the wing surfaces using the least-square fit method, which is provided by pythonOCC, to generate analysis-suitable geometry.

# To reparametrize the wing surfaces, we fist evaluate a list of

# points on them and use their locations to construct new NURBS

# patches with maximal continuity.

# Number of points to evaluate in one direction.

num_pts_eval = [16]*num_surfs

# Number of knots to insert in u and v parametric directions at

# the first refinement level.

u_insert_list = [8]*num_surfs

v_insert_list = [8]*num_surfs

# Refinement level for each patch.

ref_level_list = [1]*num_surfs

# For the two small NURBS patches at the wingtip, we control the

# refinement level less than 3 to prevent over refinement.

for i in [4,5]:

if ref_level_list[i] > 4:

ref_level_list[i] = 2

elif ref_level_list[i] <=4 and ref_level_list[i] >= 1:

ref_level_list[i] = 1

# Number of knots to insert.

u_num_insert = []

v_num_insert = []

for i in range(len(u_insert_list)):

u_num_insert += [ref_level_list[i]*u_insert_list[i]]

v_num_insert += [ref_level_list[i]*v_insert_list[i]]

Initializing the preprocessing instance by passing list wing_surfaces to OCCPreprocessing and setting both arguments reparametrize and refine as True.

preprocessor = OCCPreprocessing(wing_surfaces, reparametrize=True,

refine=True)

Then we can use the defined lists num_pts_eval, u_num_insert, and v_num_insert to reconstruct and refine the NURBS surfaces. geom_scale is used to convert the length unit. Reconstructed NURBS surfaces could have densely distributed knots, which can be removed by setting remove_dense_knots as True with tolerance rtol. The knots may not be successfully removed if the tolerance is too small, or the reconstructed surfaces may change to strange shapes if the tolerance is too large. For a detailed explanation of each argument, please refer to the help information of the following methods.

preprocessor.reparametrize_BSpline_surfaces(num_pts_eval, num_pts_eval,

geom_scale=geom_scale,

remove_dense_knots=True,

rtol=1e-4)

preprocessor.refine_BSpline_surfaces(p, p, u_num_insert, v_num_insert,

correct_element_shape=True)

And the last but important step in preprocessing is to compute the surface-surface intersections and obtain related data. This can be done using method compute_intersections in preprocessor. We set mortar_refine equals 2 so that the default numbers of elements for mortar meshes will be doubled, which will improve the stress distribution quality near the intersection.

int_data_filename = "eVTOL_wing_int_data.npz"

if os.path.isfile(int_data_filename):

preprocessor.load_intersections_data(int_data_filename)

else:

preprocessor.compute_intersections(mortar_refine=2)

preprocessor.save_intersections_data(int_data_filename)

We can print out necessary information such as total DoFs and number of intersections:

if mpirank == 0:

print("Total DoFs:", preprocessor.total_DoFs)

print("Number of intersections:", preprocessor.num_intersections_all)

There are 5208 DoFs in total and 87 intersections in the wing geometry.

Users can choose to visualize the reconstructed NURBS patches and intersections using the following code:

display, start_display, add_menu, add_function_to_menu = init_display()

preprocessor.display_surfaces(display, save_fig=True)

preprocessor.display_intersections(display, save_fig=True)

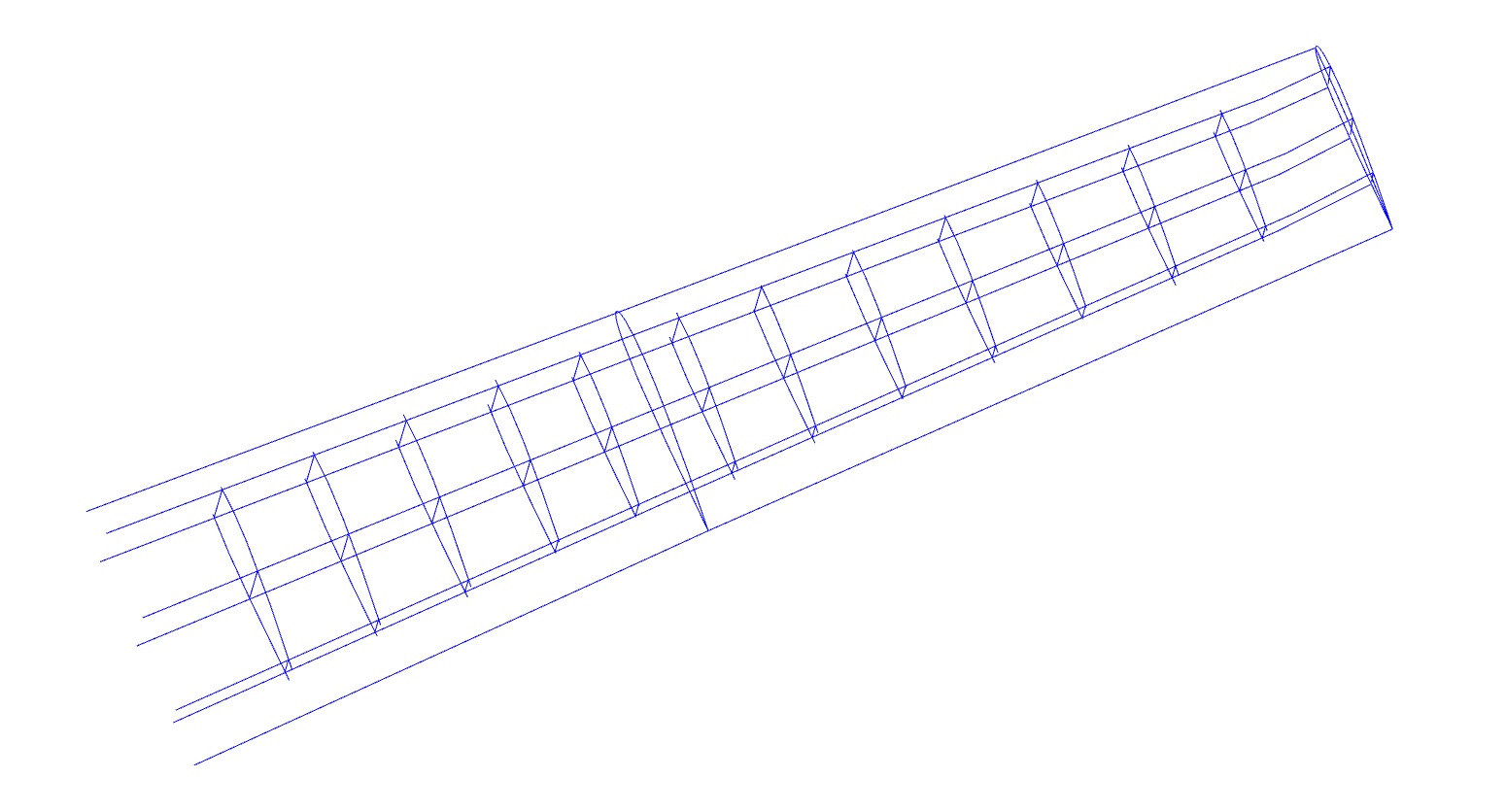

Figures of reparametrized eVOTL wing and intersections are shown below:

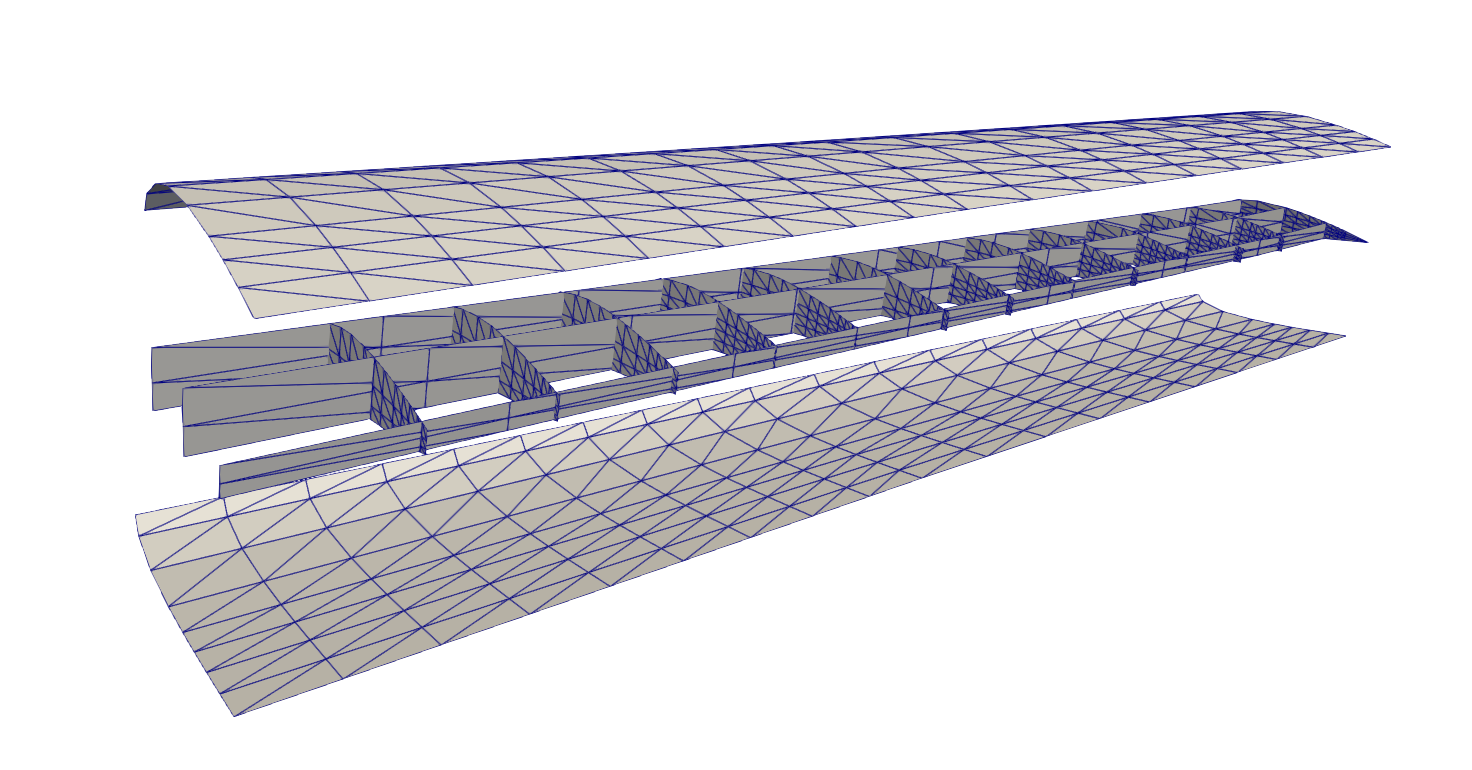

The following figure displays exploded view of the eVTOL wing geometry, where the lower and upper surfaces are transformed vertically to show the internal stiffeners.

Analysis of eVTOL wing

We now have access to all the geometry information to perform analysis for the eVTOL wing. The starting point is creating tIGAr extracted splines for all the OCC NURBS surfaces. Therefore, the following functions are defined to set clamped boundary conditions and create extracted splines, respectively.

def clampedBC(spline_generator, side=0, direction=0):

"""

Apply clamped boundary condition to spline.

"""

for field in [0,1,2]:

# Only fix one layer in y(spanwise)-direction

if field in [1]:

n_layers = 1

else:

n_layers = 2

scalar_spline = spline_generator.getScalarSpline(field)

side_dofs = scalar_spline.getSideDofs(direction, side,

nLayers=n_layers)

spline_generator.addZeroDofs(field, side_dofs)

def OCCBSpline2tIGArSpline(surface, num_field=3, quad_deg_const=4,

setBCs=None, side=0, direction=0, index=0):

"""

Generate ExtractedBSpline from OCC B-spline surface.

"""

quad_deg = surface.UDegree()*quad_deg_const

DIR = SAVE_PATH+"spline_data/extraction_"+str(index)+"_init"

# spline = ExtractedSpline(DIR, quad_deg)

spline_mesh = NURBSControlMesh4OCC(surface, useRect=False)

spline_generator = EqualOrderSpline(worldcomm, num_field, spline_mesh)

if setBCs is not None:

setBCs(spline_generator, side, direction)

# spline_generator.writeExtraction(DIR)

spline = ExtractedSpline(spline_generator, quad_deg)

return spline

The created instances of tIGAr extracted spline are stored in a list, where the clamped boundary conditions are applied to the first two patches (the upper and lower surfaces near the wing root).

# Create tIGAr extracted spline instances

splines = []

for i in range(num_surfs):

if i in [0, 1]:

# Apply clamped BC to surfaces near root

spline = OCCBSpline2tIGArSpline(

preprocessor.BSpline_surfs_refine[i],

setBCs=clampedBC, side=0, direction=0)

splines += [spline,]

else:

spline = OCCBSpline2tIGArSpline(

preprocessor.BSpline_surfs_refine[i])

splines += [spline,]

Similar to the procedures in benchmark problems, we can initialize the instance of the non-matching problem with the list splines and set up the mortar meshes using the attributes from preprocessor.

problem = NonMatchingCoupling(splines, E, h_th, nu, comm=worldcomm)

problem.create_mortar_meshes(preprocessor.mortar_nels)

problem.mortar_meshes_setup(preprocessor.mapping_list,

preprocessor.intersections_para_coords,

penalty_coefficient)

Considering a distributed upward load with value 40254 N/m^2 to simulation the working condition of an aircraft wing, then we can formulate the PDE residuals.

load = Constant(40254)

f1 = as_vector([Constant(0.0), Constant(0.0), load])

loads = [f1]*num_surfs

source_terms = []

residuals = []

for i in range(num_surfs):

source_terms += [inner(loads[i], problem.splines[i].rationalize(

problem.spline_test_funcs[i]))*h_th*problem.splines[i].dx]

residuals += [SVK_residual(problem.splines[i], problem.spline_funcs[i],

problem.spline_test_funcs[i], E, nu, h_th, source_terms[i])]

problem.set_residuals(residuals)

Finally, we are ready to perform the linear structural analysis for the eVTOL wing.

problem.solve_linear_nonmatching_problem()

Printing the vertical displacement of the trailing edge tip.

right_srf_ind = 3

xi = array([1, 1])

z_disp_hom = eval_func(problem.splines[right_srf_ind].mesh,

problem.spline_funcs[right_srf_ind][2], xi)

w = eval_func(problem.splines[right_srf_ind].mesh,

problem.splines[right_srf_ind].cpFuncs[3], xi)

QoI = z_disp_hom/w

print("Trailing edge tip vertical displacement: {:10.8f}.\n".format(QoI))

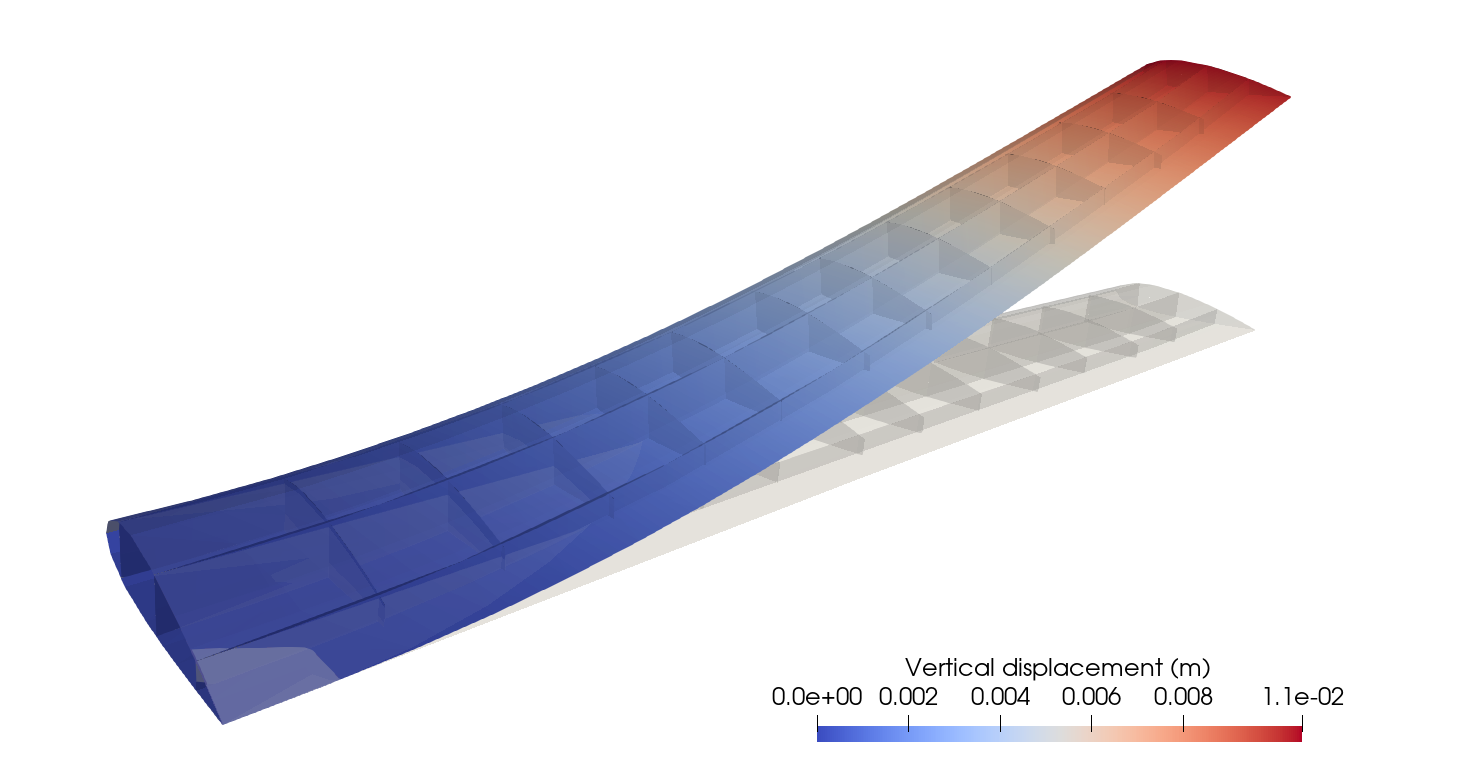

We will get the following output, where the vertical displacement of the trailing edge tip is 0.01066819 m.

Trailing edge tip vertical displacement: 0.01066819.

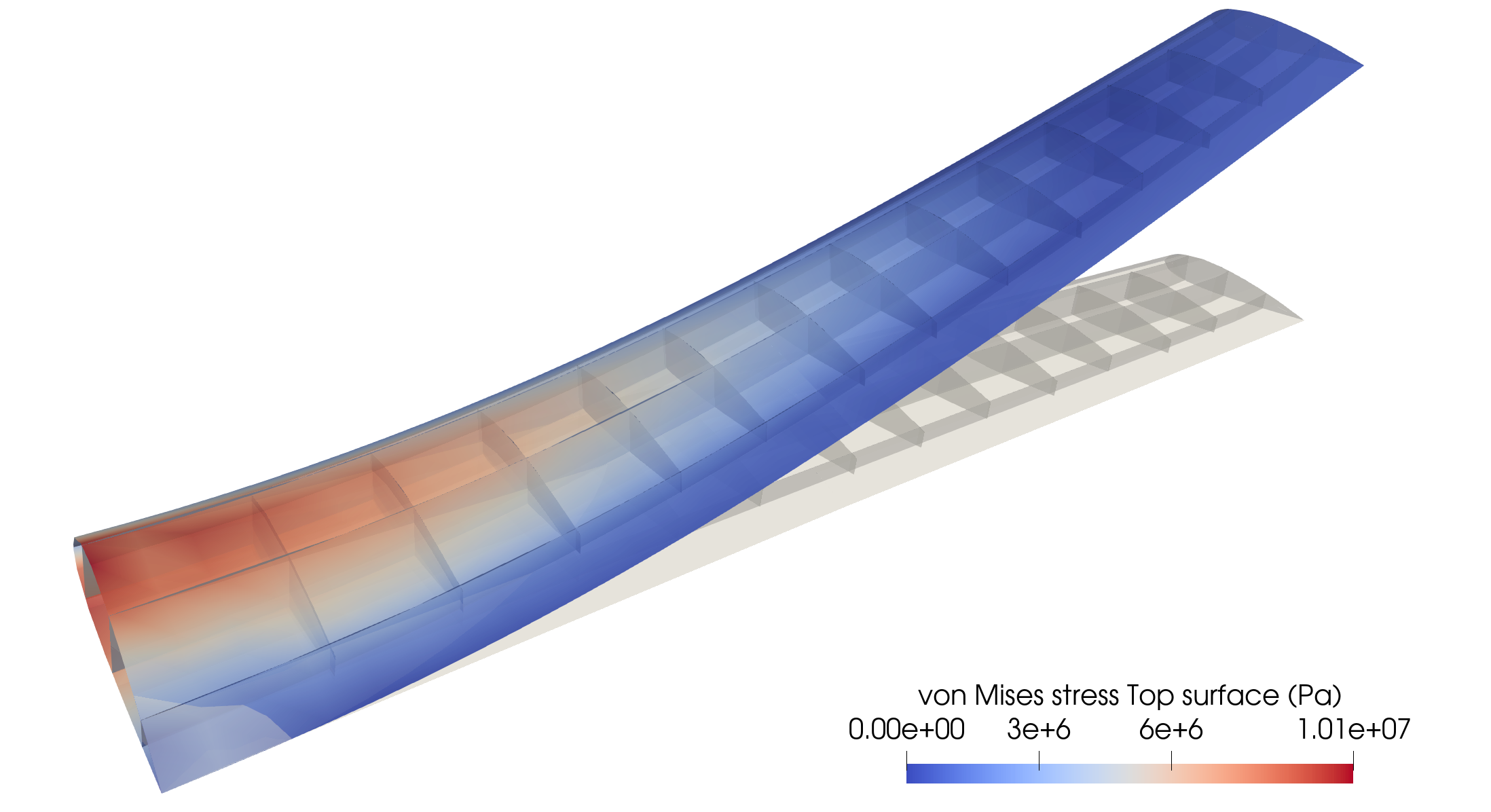

Saving displacement functions to pvd files. The vertical displacement distribution of the eVTOL wing is shown below, where the wing displacement is scaled by a factor of 10.

SAVE_PATH = "./"

FOLDER_NAME = "results/"

save_disp = True

if save_disp:

for i in range(problem.num_splines):

save_results(splines[i], problem.spline_funcs[i], i,

save_path=SAVE_PATH, folder=FOLDER_NAME,

save_cpfuncs=True, comm=worldcomm)

While the shell displacements are available, they can be passed to class ShellStressSVK in ShNAPr to compute the von Mises stresses. Since we are doing the linear structural analysis, the argument linearize has to be True. G_det_min is the minimum determinant value of metric tensor, passing a value that is a bit larger than 0 helps reduce stress concentration near the surface singularities. The stresses at the positive half thickness surfaces along through thickness coordinate are computed, and figure of von Mises stress distribution is attached.

von_Mises_tops = []

for i in range(problem.num_splines):

spline_stress = ShellStressSVK(problem.splines[i],

problem.spline_funcs[i],

E, nu, h_th, linearize=True)

# von Mises stresses on top surfaces

# Due to direction of A2, top surface: xi2 = -h_th/2

von_Mises_top = spline_stress.vonMisesStress(-h_th/2)

von_Mises_top_proj = problem.splines[i].projectScalarOntoLinears(

von_Mises_top, lumpMass=False)

von_Mises_tops += [von_Mises_top_proj]

save_stress = True

if save_stress:

for i in range(problem.num_splines):

von_Mises_tops[i].rename("von_Mises_top_"+str(i),

"von_Mises_top_"+str(i))

File(SAVE_PATH+FOLDER_NAME+"von_Mises_top_"+str(i)+".pvd") \

<< von_Mises_tops[i]